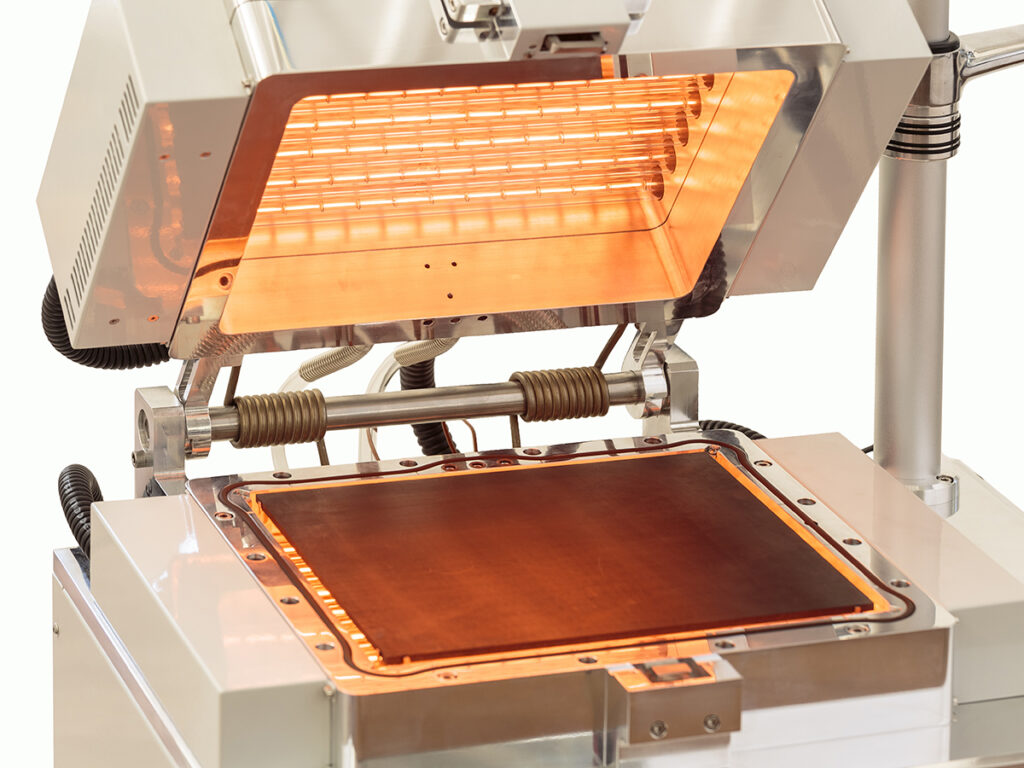

Vacuum technology delivers superior results across soldering applications. Key benefits include:

Removal of moisture and oxygen with nitrogen backfill

Faster, deeper surface cleaning with formic acid

Quick residue removal after cleaning

Void reduction during molten solder phase

Vacuum cooling for hermetic encapsulation

Contact us today for more information: [email protected] or visit our contact us page for your local sales person.

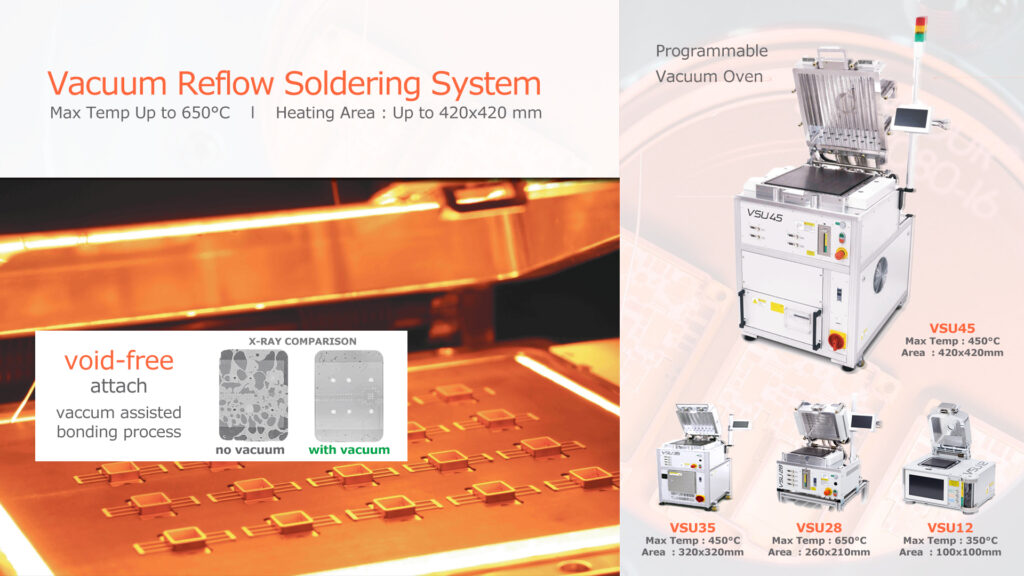

Void-Free Solder Joints

- During reflow, chamber evacuation removes voids as bubbles escape the molten solder, reducing voids to under 5%. For large solder areas (e.g. IGBT), bubbles may remain trapped. In this case, applying positive pressure (2–3 bar) after vacuum further compresses and removes bubbles, ensuring excellent void reduction.