Founded in Germany in 1996, TPT develops high-precision bonding systems that are easy to use and highly versatile. Our manual, semi-automatic, and fully automatic bonders can handle a wide range of materials—including gold, aluminum, copper, titanium, and insulated wire—and perform multiple bonding types simply by changing the tool. Perfect for both production and prototyping, TPT systems combine flexibility, precision, and reliability in every application.

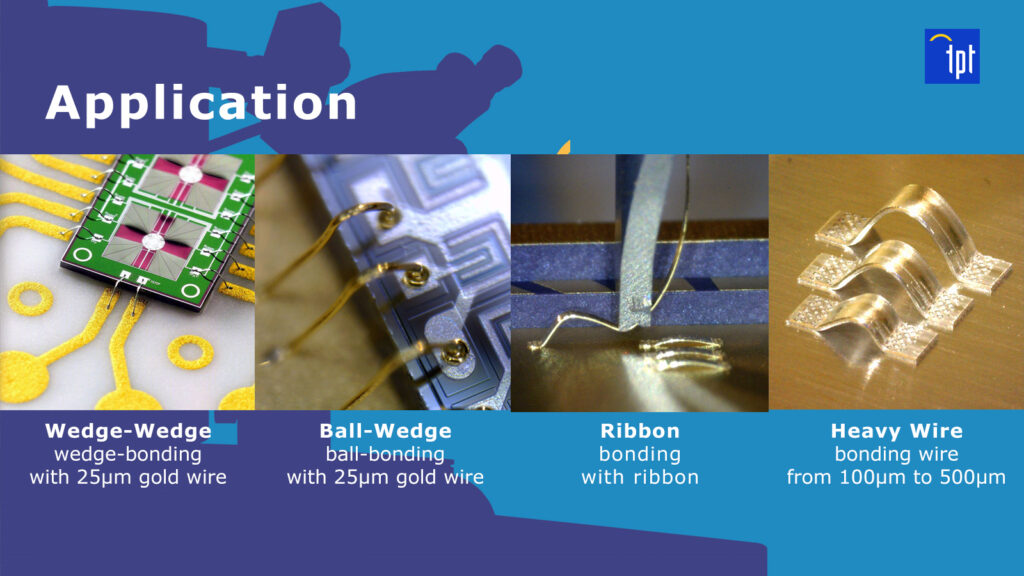

Wire Bonding Applications

TPT bonders support ball, wedge, ribbon, stud bump, and insulated wire bonding with just a tool change and easy programmable parameters change. They handle gold, aluminum, copper, titanium, and more—ideal for R&D, prototyping, and specialized production.

Die Bonder Applications

Die bonding, or chip bonding, is the process of attaching components to a PCB, wafer, or substrate. Adhesive is first applied by dispensing or stamping tool, then the die is picked up with vacuum and placed on the adhesive. Programable downforce and time ensures stable, repeatable results. This “pick & place” step typically precedes wire bonding.